Are Nonstick Pans Really Toxic When Scratched? A Scientific Breakdown

Why Scratched Nonstick Pans Raise Health Concerns

Nonstick cookware has become a staple in modern kitchens due to its convenience, easy cleaning, and reduced need for cooking oil. However, concerns about scratched nonstick pans and their potential health risks have intensified over the past decade. Many consumers wonder whether damaged coatings can release toxic substances into food and whether these risks are supported by scientific evidence.

This article provides a detailed, science-based analysis of scratched nonstick cookware, examining what happens when coatings degrade, what chemicals may be involved, and how real-world usage affects safety.

What Are Nonstick Pans Made Of?

Most traditional nonstick pans are coated with polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon. PTFE is a synthetic fluoropolymer prized for its heat resistance, chemical stability, and extremely low friction.

Earlier generations of nonstick cookware were manufactured using perfluorooctanoic acid (PFOA) during production. PFOA raised serious health concerns and has since been phased out in many countries. Modern nonstick pans are generally labeled as PFOA-free, but PTFE remains the primary coating material.

What Happens When a Nonstick Pan Gets Scratched?

Scratches occur due to metal utensils, abrasive sponges, stacking pans without protection, or overheating. When the surface is scratched, the PTFE coating can flake or degrade, raising two main concerns:

- Physical ingestion of coating particles

- Chemical degradation at high temperatures

Scientific studies indicate that PTFE itself is chemically inert and poorly absorbed by the human digestive system. If small flakes are ingested, they typically pass through the body without accumulating in tissues.

Can Scratched Nonstick Pans Release Toxic Chemicals?

The primary health risk associated with nonstick cookware is not scratching alone but overheating. When PTFE coatings are heated above approximately 260°C (500°F), they begin to degrade and release fumes that may cause polymer fume fever — a temporary flu-like condition.

Importantly, normal stovetop cooking rarely reaches these temperatures unless pans are preheated empty or used improperly. Scratches themselves do not significantly increase chemical release unless combined with excessive heat.

Scientific Evidence on PTFE Safety

Multiple regulatory agencies, including the U.S. Food & Drug Administration (FDA) and the European Food Safety Authority (EFSA), have evaluated PTFE cookware safety. Their findings consistently indicate that PTFE-coated cookware is safe for consumer use when used according to manufacturer guidelines.

Studies examining PTFE ingestion have found no evidence of carcinogenicity or bioaccumulation in humans. The main safety threshold is temperature control rather than surface appearance.

Real-World Example: Professional Kitchens

Professional chefs often avoid traditional nonstick cookware not primarily due to toxicity concerns, but because scratched surfaces compromise cooking performance. Stainless steel and cast iron dominate professional kitchens, where durability and heat tolerance are prioritized.

In a documented interview conducted by food safety researchers studying commercial kitchen practices, chefs emphasized equipment longevity and predictable heat behavior rather than chemical exposure concerns.

When Should You Stop Using a Scratched Nonstick Pan?

Scientific and regulatory guidance suggests replacing nonstick cookware when:

- The coating is peeling or flaking extensively

- Food consistently sticks despite proper use

- The pan has been overheated repeatedly

Minor surface scratches alone do not automatically render cookware unsafe, but visible deterioration combined with high-heat cooking increases risk.

Are Newer Nonstick Alternatives Safer?

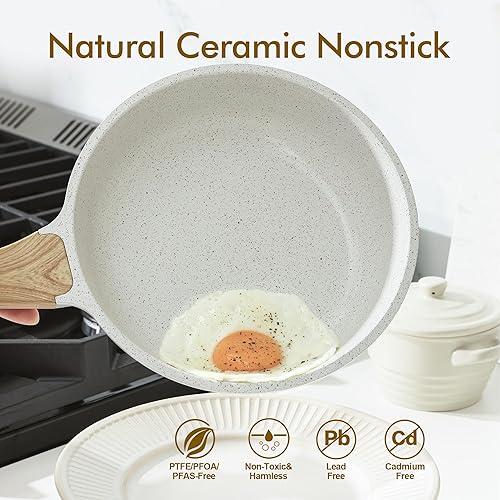

To address consumer concerns, manufacturers have introduced ceramic-based coatings, anodized aluminum, and hybrid surfaces. While marketed as safer alternatives, these coatings still require careful temperature control and proper utensils.

Scientific data on long-term ceramic coating durability is still limited, and many ceramic pans lose nonstick performance faster than PTFE-based cookware.

Amazon Picks: Safer Cookware Alternatives

Stainless Steel Frying Pan

Durable, scratch-resistant cookware ideal for high-heat cooking without chemical coatings. A preferred choice for professional chefs.

Ceramic Nonstick Pan

PTFE-free alternative designed for low-to-medium heat cooking, offering easier food release with fewer synthetic chemicals.

Choosing appropriate cookware materials can significantly reduce long-term concerns related to surface degradation and heat exposure.

Do Scratches Increase Aluminum or Metal Exposure?

Another common concern is whether scratches expose the aluminum base beneath the nonstick coating. Aluminum cookware is typically anodized or layered to prevent direct food contact. Even when minor scratches occur, studies show that aluminum migration into food remains extremely low and well below established safety thresholds.

The World Health Organization has stated that dietary aluminum exposure from cookware is minimal compared to natural dietary sources. Acidic foods may slightly increase aluminum leaching, but the contribution from cookware remains negligible for healthy individuals.

Comparing Scratched Nonstick to Other Cookware Risks

All cookware types carry some degree of risk when misused. Stainless steel may release nickel in sensitive individuals, cast iron increases iron intake, and ceramic coatings may degrade unevenly over time. Scratched nonstick pans are not uniquely dangerous, but they require proper handling.

From a risk assessment perspective, temperature control, cooking habits, and maintenance practices matter more than surface aesthetics.

Real-Life Example: Home Cooking Habits & Exposure

In population-based dietary exposure assessments conducted by public health agencies, cookware-related chemical exposure accounted for a very small fraction of total intake. Studies examining household kitchens found that improper heating practices were the strongest predictor of exposure risk, not cookware age or appearance.

This reinforces the idea that informed use is more important than immediate replacement at the first sign of cosmetic damage.

Best Practices for Using Nonstick Pans Safely

- Avoid preheating empty nonstick pans

- Use wooden, silicone, or nylon utensils

- Keep cooking temperatures below medium-high heat

- Hand wash instead of using abrasive dishwashers

- Replace pans with visible peeling or flaking

Following these guidelines significantly reduces any potential risks associated with scratched nonstick cookware.

Conclusion

Scratched nonstick pans are not inherently toxic. Scientific evidence consistently shows that PTFE coatings are stable and non-reactive under normal cooking conditions. The primary risk arises from overheating rather than surface wear.

Consumers do not need to discard cookware at the first sign of scratching. Instead, understanding proper use, temperature limits, and maintenance practices offers a more effective approach to minimizing risk while extending cookware lifespan.

For those seeking alternatives, stainless steel, cast iron, and glass cookware provide durable and safe options when used appropriately.

Scientific References

- U.S. Food & Drug Administration (FDA). PTFE Safety Assessment for Cookware Applications.

- European Food Safety Authority (EFSA). Perfluorinated Compounds & Consumer Exposure.

- World Health Organization. Evaluation of Certain Food Additives and Contaminants: Aluminum.

- National Institute for Occupational Safety and Health (NIOSH). Polymer Fume Fever and PTFE Decomposition.

- Agency for Toxic Substances and Disease Registry (ATSDR). Toxicological Profile for Fluoropolymers.

Disclaimer

This article is for informational purposes only and does not constitute medical or professional advice. We do not assume responsibility for individual outcomes based on the use of cookware or dietary choices.